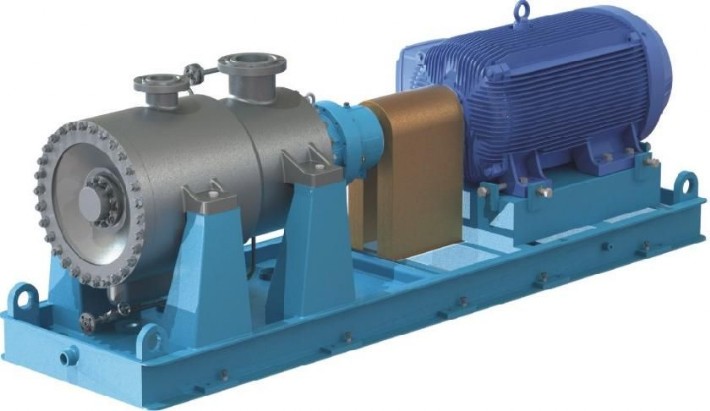

Dichtungslose Pumpen nach API 685

Hermetisch dichte Pumpen mit Magnetkupplung nach API 685

für den Einsatz in der Petroindustrie

Die Spezifikation API 685 Seal-less Centrifugal Pumps for Petroleum,

Heavy Duty Chemical and Gas Industry Services definiert die Ausführung und

Spezifikation für dichtungslose Pumpen in petrochemischen Anlagen und

Raffinerien

API 685 Ausführung, doppelter Magnettopf mit Leckageüberwachung

- Temperaturbereich: -150°C bis +450°

- In Edelstahl , Hastelloy oder Alloy 20, 316 Stl Stl / HC / Duplex

- Dichtungslos - Emmissionsfrei DIN 22858

- Ausführung Hochdruckausführung bis 130 bar

- Differenzdruck, Hochdruckausführung bis 700bar Systemdruck

- Ideal für: Prozesschemie, Raffinerien, Petrochemie, Pharmazie, Radioaktive und giftige Flüssigkeiten, Thermalöle, Kältemittel

+++++++++++++

The CN MAG-M API pumps from M Pumps are heavy duty centreline-mounted

centrifugal pumps,

designed for the Petrochemical industries.

These

magnet drive leak free pumps are back pullout design single stage volute

casing pumps with closed impellers

that meet the performance and

dimensional requirements of API 685.

As well as different material

options, high temperature and high system pressure versions of the CN

MAG-M API series are also available.

Weitere Pumpen anch API 610 für konventionelle Kreiselpumpen.

CN MAG-MS API

These multi-stage centrifugal pumps from M Pumps conform to the

requirements of API 685

and are designed for high differential head

applications in the petrochemical sector.

- Capacities to 300 m3/hr

- Differential heads to 700 metres

- Maximum system pressure to 100 bar

All the CN MAG-MS API ranges are magnetically coupled and so are leak

free,

making them ideal for pumping hazardous, toxic and dangerous

liquids safely.

M Pumps' patented energy saving hybrid rear casing

technology is available on the CN MAG-MS API series,

helping to keep

operating costs to a minimum.

Features & Benefits

| Feature | Benefit |

| Hermetically sealed, leak free design | No rotating seals to fail means reduced downtime and less lost

production, no cross contamination of the pumped liquid, no process

fluid wastage, no environmental hazards due to leaks, increased

operator's safety with process fluid containment |

| Choice of chemical-resistant wetted materials | Extend pump life and increase time between servicing |

| Secondary containment options available | Prevents any leakage in the event of ball bearing failure |

| Patented hybrid rear magnet-can design available | Reduces power required, improves energy efficiency |

| Barrel design - one piece casting | Reduced environmental hazard |

| Low flow pumping at high differential heads | No need to bypass excess flow, simple installation |